The ANDRITZ group offers a broad portfolio of innovative plants, equipment, and services for various industries. Panelboard supplies innovative single equipment and complete front-end packages (debarking, chipping and screening, chip handling, chip washing, pressurized refining systems, wastewater evaporation). Our machines process any kind of wood or annual fibers, such as bagasse, bamboo or straw. Extensive system and process know-how for panelboard fiber preparation is the technological base of our solution, which also comprises responsive service, replacement parts, and upgrades to existing machines. Low electrical and thermal energy consumption with best performance is the driving factor for the design of each machine in the system and the process. ANDRITZ offers rebuilds, spare and wear parts, upgrades, and on-site services for equipment from virtually any OEM. Services to the panelboard industry are provided through a worldwide network of technical and field service specialists.

Business profile

Machinery & Technology

Our Solutions/Product Highlight

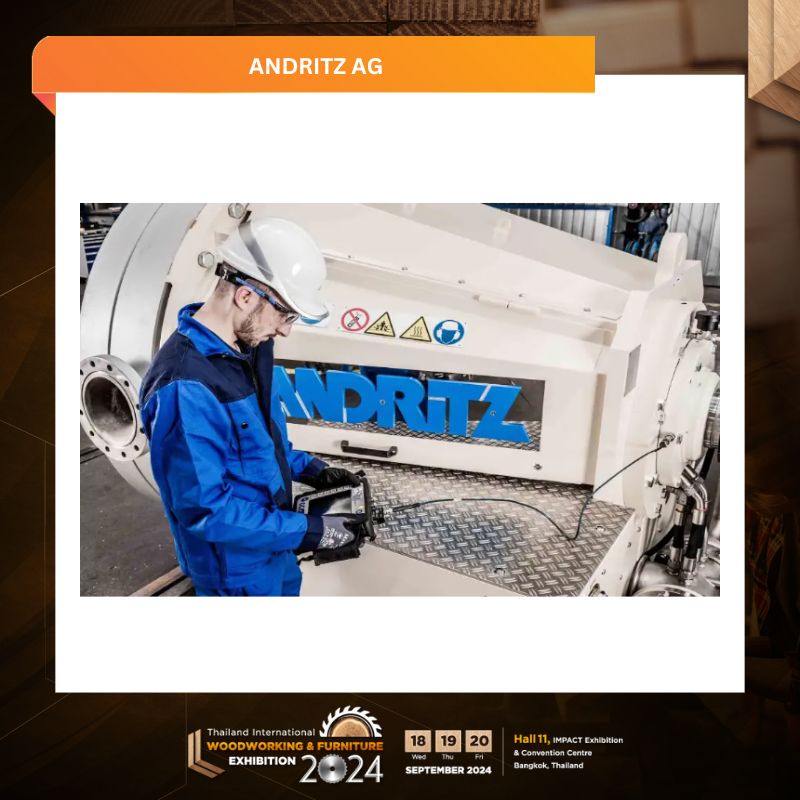

Pressurized refiner

The heart of the fiber preparation process is the pressurized refiner. It is sized to specific requirements to produce high-quality fiber with low energy consumption. Each refining system is designed to last. Top performance, high reliability, and availability are hallmarks of our HC-refiners, which ensure trouble-free operation and ease of maintenance, even in demanding applications (processing veneer chips, shavings, sawdust, waste wood). The innovative “swing-door” design of our refiners makes it easy and quick to change refiner plates. With the addition of the latest process control and plant instrumentation, our customers receive a complete, highly sophisticated front-end system from a single source. No matter what the capacity, our technology is designed to deliver top performance. ANDRITZ has designed and delivered the world’s largest single-stage MDF pressurized refining system. Decades of experience allow us to understand the processes well. That is why we can offer full-line solutions when needed.